One New Way of Making Low-carbon Cement

Even cement production can be electrified, for a 90% reduction in GHGs

We were awe-struck when we first visited the Pantheon temple in Rome. The building was built nearly 2,000 years ago out of concrete, and it remains in nearly original condition.

The concrete the Romans used was not the same as modern concrete, and often included pozzolanic ash found in Italy, along with other cementitious binders.

We still rely heavily on concrete. As Professor Vaclav Smil points out in his 2022 book “How The World Really Works”:

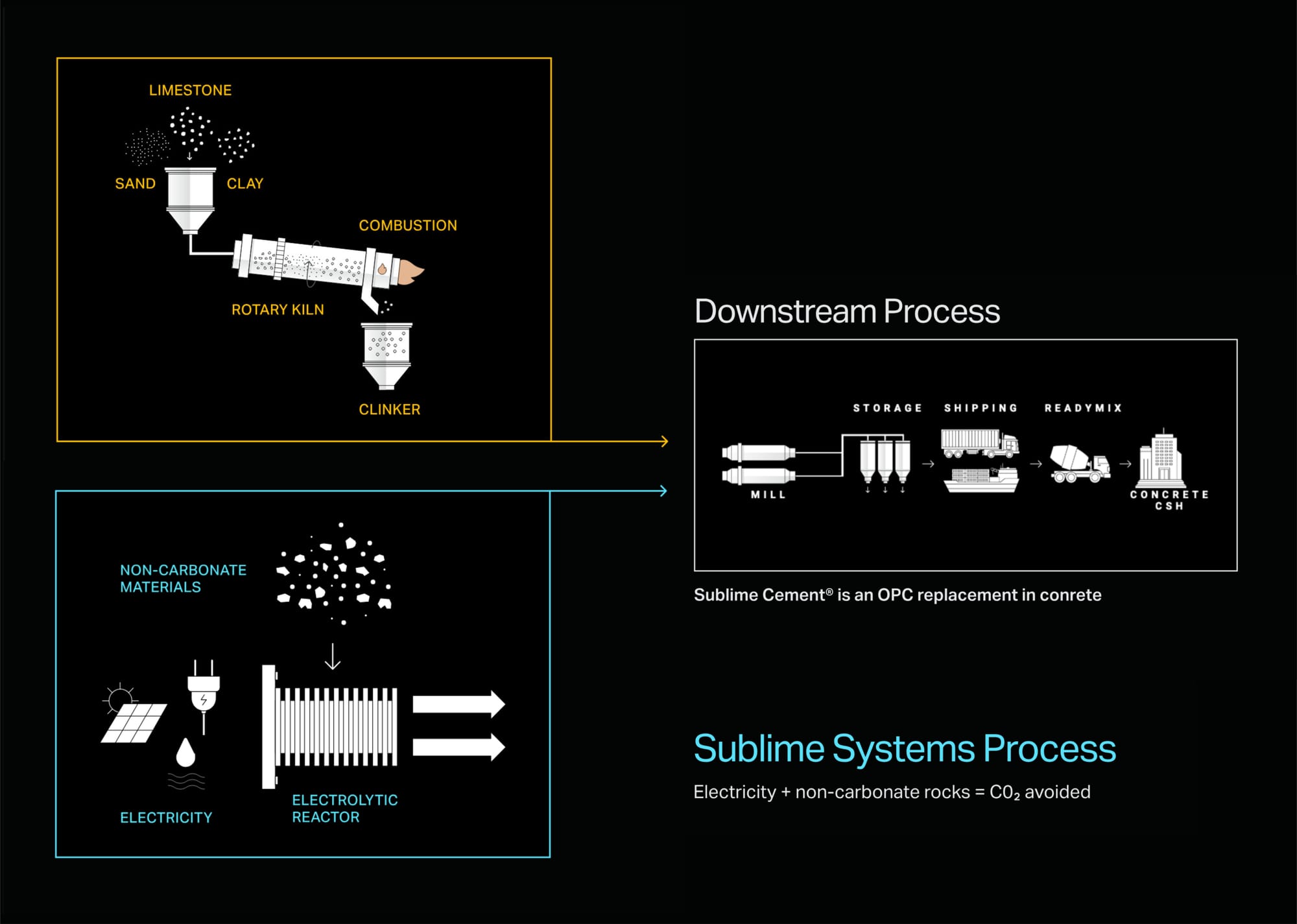

Making Portland cement is a complicated multi-step process, but it usually involves heating limestone at temperatures up to 1450 degrees Celsius by burning fossil fuels. The heating process also releases CO2 directly from the limestone. The incorporation of Portland cement in concrete accounts for most of the concrete industry’s greenhouse gas (GHG) footprint, which is about 8% of the worldwide total, more than the aviation industry.

Many people and organizations are working on ways of reducing concrete’s GHG footprint, mostly by searching for alternatives to Portland cement. Some alternatives show promise.

Rather than burning limestone at high temperatures, their process produces an alternative non-limestone-based cement that can directly replace Portland cement without altering the rest of the concrete production process.1

Sublime’s process reduces the GHG emissions by about 90% to 72 kg CO2/tonne, compared to the 922 kg CO2/tonne for industry-wide average Portland cement in the United States.2

Some projects are currently being built of concrete using Sublime's cement. The Sublime process is being scaled up from the current pilot plant to a modular production plant, opening in 2026, that will produce 30,000 tons per year.

This development will not de-carbonize the entire building industry on its own, but there never was a silver bullet.

Sweet Lighting is not in any way associated with Sublime Systems.

Reading

- Ellis, Leah D., Andres F. Badel, Miki L. Chiang, Richard J.-Y. Park, and Yet-Ming Chiang. “Toward Electrochemical Synthesis of Cement—An Electrolyzer-Based Process for Decarbonating CaCO3 While Producing Useful Gas Streams.” Proceedings of the National Academy of Sciences 117, no. 23 (2020): 12584–91. https://doi.org/10.1073/pnas.1821673116.

- Glabets, Erin. “Sublime Systems Receives Life Cycle Assessment Validating Its Electrified Cement Manufacturing Process Enables >90% Greenhouse Gas Emissions Reduction.” Sublime Systems, October 26, 2023. https://sublime-systems.com/sublime-systems-receives-life-cycle-assessment-validating-its-electrified-cement-manufacturing-process-enables-90-greenhouse-gas-emissions-reduction/.