Oil Shocks and Microchips

How buildings learned to stop wasting and start thinking

The story of how engineers began to get a grip on energy flows within large buildings to improve control and reduce energy consumption.

Large modern buildings are surprisingly complex in design and operation. Nearly everything is connected to everything else, but it wasn’t always this way. Prior to the late 1920s, most buildings, even large ones, had windows in every space. Heating was simple—radiators on outside walls, and if you wanted to cool off, you opened a window, which let in fresh air. Floor plate plans for buildings were necessarily narrow, and often had many bumps and indents to provide those windows.

The invention of mechanical air-conditioning allowed buildings, for the first time, to be built with large floor plates containing functional interior rooms that weren’t directly connected to the outside, like the 21-story Milam Building in San Antonio, Texas in 1928.1 Now engineers had a problem. Those interior spaces, beyond, say, about 5 metres from the outside walls, needed lights during the day, and the people working in them needed fresh air. The lights and people generated heat that couldn’t dissipate through the outside walls. The fresh air from outside might not be cool enough for much of the year to remove the heat. Mechanical cooling was needed year-round. In addition, the spaces located on the outside walls might need cooling from the incoming sunshine on one side of the building while at the same time the spaces on the opposite side might need heating.

The solution was to provide mechanically-cooled air cold enough to remove the heat from the warmest spaces and to heat the air back up for the spaces that didn’t need as much cooling, or perhaps that even needed heat. Ironically, while the occupants could be nice and cool in hot weather thanks to the air-conditioning, the buildings frequently also had to run their heating boilers year-round to warm some of the air back up. For the next several decades, most large building mechanical systems were essentially variations on that basic design principle. It was a brute force approach that was horribly wasteful (when I first encountered this approach at the beginning of my engineering design career I was appalled by its inelegance), but energy was cheap and better control was expensive.

- OPEC

The first OPEC (Organization of Petroleum Exporting Countries) oil embargo in 1973 caused a massive oil price shock. The reasons for that embargo and price rise were extremely complicated, but the upshot of it in the USA was oil prices in late 1973 that were six times higher than three years previous.2 The high prices caused everyone who was responsible for operating or designing buildings to start seriously examining the issue of energy use, and to look for ways to lower the cost by reducing the waste. Had oil prices not precipitously shot up, serious change would likely have taken much longer to begin.

- Building-Energy Simulation Programs

Typical engineering practice in the early ‘70s was to design building mechanical systems to have sufficient capacity at peak heating and peak cooling times and not worry too much about what happened on off-peak, part-load times, which, by definition, are most of the year. Engineers did not have a good understanding of how energy was used by the various subsystems in buildings, nor did they have a good grasp of how those systems interacted and performed at part load conditions. Since the 1960s, some researchers realized that computers, along with decades of hourly weather data, could help. Computer programs that could simulate the many systems in a building, their interactions with each other, and with outside weather conditions, were slowly developed.3 In response to the oil price shocks, progress on these programs accelerated. By the mid-70s, some programs became available for commercial use.

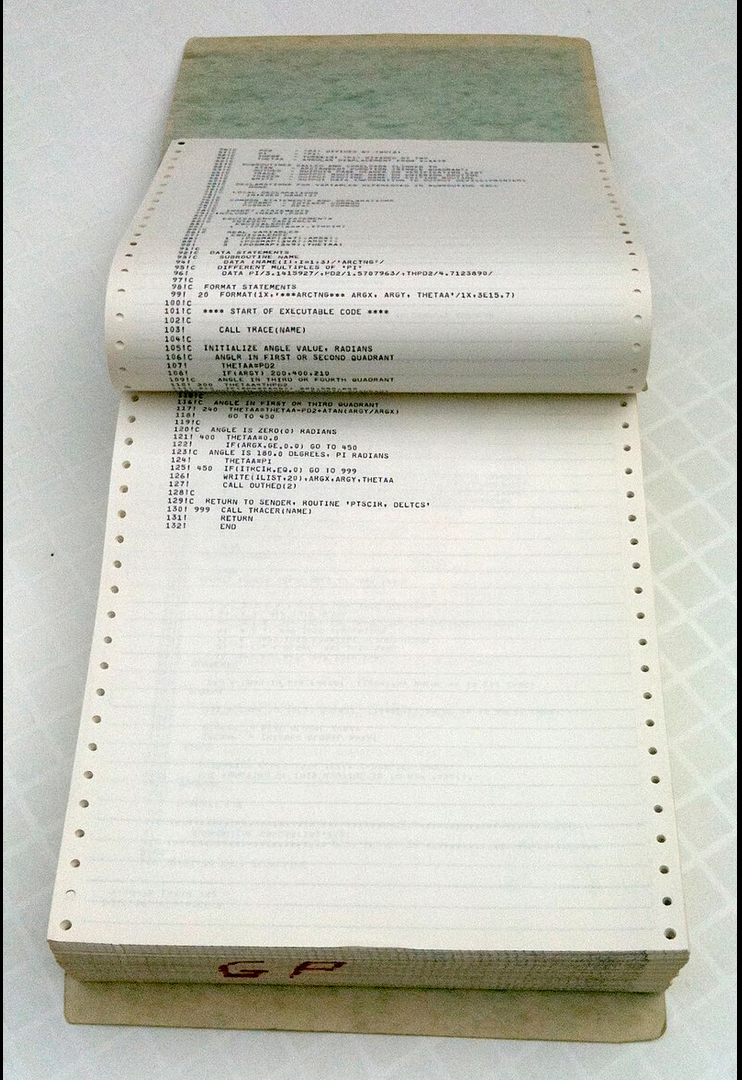

Those early hour-by-hour building energy simulation programs were slow and cumbersome to run. They ran in batches on mainframe computers which were often located half a continent away from those using the programs. Input was via arcane computer language instructions on punch cards, boxes of them for a large simulation. Getting results from a run often took hours, and were delivered back to you on large stacks of fan-fold paper. One error on one card, or one card out of order, could render the whole run invalid. I still carry a painful memory of dropping a box full of several hundred input cards into a snow bank, while on the way to the building that housed the mini-computer that read the cards and transmitted the program over a modem to the mainframe.

Still, even with all the difficulties in getting a clean run, the resulting simulations provided insights into design and performance that could not be obtained any other way. What-if questions could be asked on system types and configurations. The relative differences in performance informed design decisions. Some results seemed counter-intuitive at first, but made sense after further investigation. One such example was that adding more exterior insulation in a cold climate to a building with a large lighting, equipment, and people load could actually increase the energy consumption by holding the heat in and turning the building into one that needed cooling all the time. Insights like that also eventually got engineers and architects talking to each other more, seeking to understand how building shape, insulation, and window choices affected what systems mechanical engineers would propose, and how the interaction affected overall energy consumption.

The models produced by the programs were not perfect. The models were better at predicting relative performance differences between design options than they were at predicting performance of real buildings. A large number of assumptions had to be made when setting up a model. I got a vivid demonstration of the model/reality difference when another engineer and I were assigned to calibrate a design energy simulation model to reflect the actual, as-built performance of the building. We spent 3 months working on it and we still hadn’t accounted for some differences.

Notwithstanding limitations, since then building energy simulation models have proliferated, become far more sophisticated, become vastly more powerful, and can run on desktop computers. They are now indispensable to contemporary design teams.

- DDC (Direct Digital Control) Revolution

Computers were also used to control building operations. In the 1960s, a few of the large controls manufacturing companies introduced mainframe computers, running proprietary software, to control buildings. Mainframe-based control systems were necessarily complex. Mainframes needed a specialized room to house the proprietary computer, hard drives, input terminals, and printers. That central location also had to house interface electronics to sense and control the building. While control logic resided in the central mainframe, the mechanical equipment that heated and cooled the water and air that conditioned the building was distributed throughout the building. As it had been for decades, motive power for the actual valves and dampers was compressed air supplied by a dedicated compressor and piping system. Each of those legacy actuators required a specialized interface device to talk to the mainframe via its own long wiring run.

The complexity of those mainframe systems meant that there were few suppliers, competition was limited, and cost was high. Computer control only made sense for large campus installations, typically ones with central heating and cooling plants. Even then, the systems were cumbersome to use, particularly the proprietary programming. Engineers and owners had to write detailed operations specifications, which were shipped off to company headquarters, where programmers wrote an entire monolithic program, and shipped it back for local installation. Turn-around time for error-correction or other changes often took months.

Moore’s Law4 was at work, though, and throughout the 1970s the large-scale integration of computer chips led to the development of microprocessors that had computing power approaching that of the older mainframes. At the same time, computerization was brought to sensors and actuators, increasing their accuracy, reducing their cost, and eliminating the need for compressed air actuation networks. By the early 1980s, microprocessors, together with the new sensors and actuators, became cheap and accessible enough that clever engineers could use them to build digital computer control systems for buildings at all scales, not just large campuses.

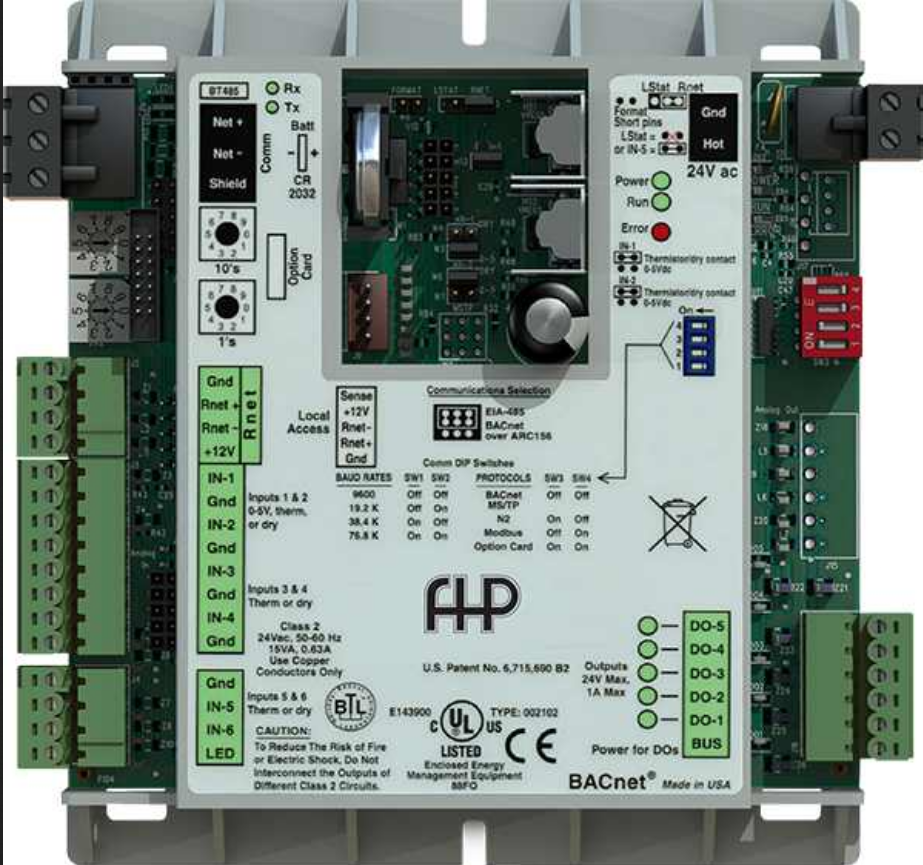

Small companies, sometimes no more than three or four individuals literally working out of their garages, developed control systems that consisted of microprocessors mounted on relatively small circuit boards that contained input and output connections tied directly to electronic sensors and actuators. The systems could be scaled by networking these boards (distributed throughout the building near the equipment being controlled) together with a simple twisted pair of wires. New electronic actuators no longer needed compressed air. One more key feature of these new systems was some form of English-like programming language (e.g. Control Basic), which could be easily learned by design engineers or building operators.

Collectively, the new technology became known in the buildings industry as DDC (Direct Digital Control). DDC was directly analogous to the SCADA (Supervisory Control and Data Acquisition) systems also being deployed in industrial systems at the time.

The advent of DDC systems for building control was a disruptive revolution. The new systems were vastly cheaper, faster to design and install, and infinitely more flexible to program. Crucially, the new distributed DDC systems gave building operators and owners the power to quickly and directly make needed changes to the programming. A number of owners of large portfolios of buildings, such as governments and universities, embraced the new technologies and worked with the DDC start-up companies to begin retrofitting existing buildings for better control, reduced energy consumption, and lower maintenance costs. Field experience with the new systems, quickly fed back to small nimble companies, led to a virtuous cycle of competition, rapid continuous improvement, and declining cost. Control of building conditions improved and operating costs came down.

Energy Use Intensity (EUI), measures the amount of energy use per square metre of building floor space, and is the most common measure of building energy efficiency.

Data on energy use in buildings in the 1960s and 1970s is scanty. A retrospective study done in 1980 on commercial buildings used very different methodology than later, more comprehensive studies, so its EUI numbers can’t be compared directly, but the trends the study identifies are likely reliable in relative terms. The study showed EUI rising by 30% between 1960 and 1973, and then essentially flattening in the last half of the decade.5 A 1992 study, working from a 1979 baseline, showed EUI declining 25% over the intervening thirteen years.6 These efficiency gains did not mean that energy use decreased for the entire building sector during that time. Increasing population, more buildings, more demand for air-conditioning, and more electronics in buildings led to an overall increase in the amount of energy used by the buildings sector.

Fortunately, reductions in the environmental impact of individual buildings, including energy use, did not stop with these early innovations, but were more of a precursor to the modern green building movement.

That, however, is another story for another time.

Reading:

- Milam High-rise Air Conditioned Building. https://www.asme.org/About-ASME/Engineering-History/Landmarks/155-Milam-High-rise-Air-Conditioned-Building (accessed 2025-07-20).

- CGEP, C. |. The 1973 Oil Crisis: Three Crises in One—and the Lessons for Today. Center on Global Energy Policy at Columbia University SIPA | CGEP. https://www.energypolicy.columbia.edu/publications/the-1973-oil-crisis-three-crises-in-one-and-the-lessons-for-today/ (accessed 2025-07-21).

- Kusuda, T. EARLY HISTORY AND FUTURE PROSPECTS OF BUILDING SYSTEM SIMULATION. , https://publications.ibpsa.org/proceedings/bs/1999/papers/bs1999_P-01.pdf (accessed 2025-07-21)

- Roser, M.; Ritchie, H.; Mathieu, E. What Is Moore’s Law? Our World in Data 2023. https://ourworldindata.org/moores-law (accessed 2025-07-22)

- Jackson, J. Energy Use in the Commercial Building Sector: Historical Patterns and Future Scenarios; National Renewable Energy Laboratory (NREL): Golden, CO (United States), 1980. https://doi.org/10.2172/1832205.

- David, J.; Swenson, A. Trends in Energy Use in Commercial Buildings - Sixteen Years of EIA’s Commercial Buildings Energy Consumption Survey.